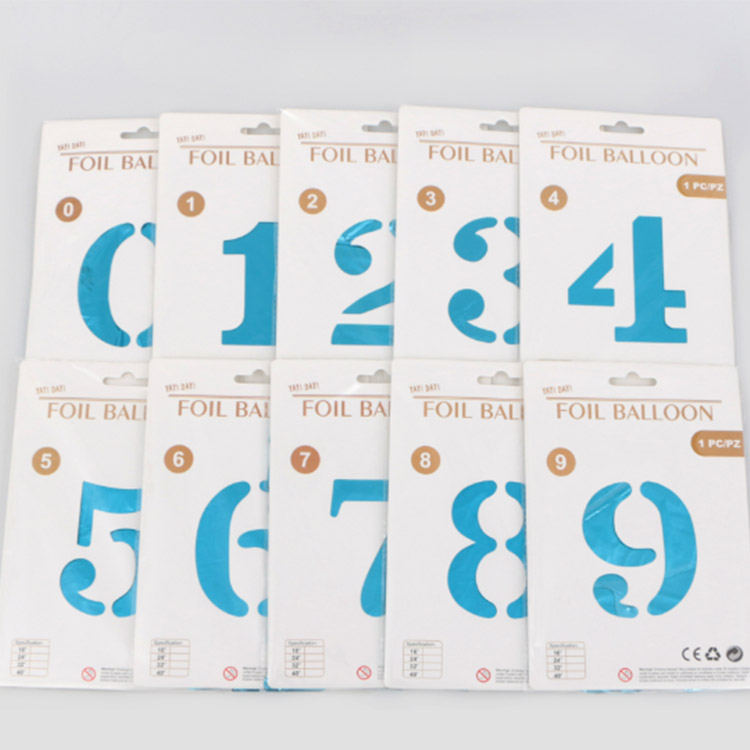

OEM Foil Balloon

OEM foil balloons, also known as personalized foil balloons, are a popular choice for parties, events, and celebrations. These balloons are made of high-quality polyester or nylon material that gives them a shiny and metallic appearance. They can be customized with personalized messages, logos, or designs according to the customer's preferences. Baoding New Shine® Import and Export Trade Co.,Ltd provides very complete foil balloon customization services, allowing you to get the perfect artwork that suits your needs.

Send Inquiry

In the highly competitive world of OEM foil balloon manufacturing, careful process and timeline planning are critical to success. From design conception to production, every step plays a vital role in delivering high-quality products on time. This blog post will delve into the complexities of OEM foil balloon production and the importance of effective process and time management.

Design phase:

The journey of OEM foil balloon production begins with the design phase. This stage involves creating innovative and eye-catching balloon designs that resonate with your target customers. Working closely with designers and manufacturers is key to ensuring the final product meets customer specifications and brand requirements.At the same time as the design is confirmed, the size of the balloon also needs to be confirmed.

Material sourcing and sampling:

Once the design of the OEM foil balloon is finalized, the next step is to source high-quality materials for production. From selecting the right material to sourcing printing inks and accessories, every aspect of the manufacturing process is carefully considered. OEM foil balloon material is divided into polyester and nylon, polyester material has good softness, transparency and chemical resistance, is a relatively tough and not easy to break the material. Compared with such as polyester materials, nylon has high strength and hardness and good wear resistance, more durable than polyester materials, the production process is relatively complex, so the price is relatively expensive. Under normal circumstances, the production of foil balloons uses polyester materials more. Balloons made from both materials can float in the air when filled with helium.

About OEM foil balloon material preservation: Nylon has good moisture and oxidation resistance, and polyester materials are good in type preservation but poor in moisture protection ability,so they need to be stored in a dry space.

Sampling and prototyping are critical steps to test the feasibility and quality of a design before mass production begins.

Production Plan:

Effective production planning is the backbone of timely delivery in OEM foil balloon manufacturing. This includes organizing production schedules, allocating resources, and ensuring quality control measures are taken at every stage of production. By streamlining production processes and optimizing workflows, manufacturers can meet tight deadlines without compromising quality.

0EM foil balloon process and time planningthe details as follow:

Quality assurance is a non-negotiable aspect of OEM foil balloon production. Strict quality control checks are carried out at all stages of production to ensure that the balloons meet industry standards and customer expectations. From color accuracy to durability, every detail is carefully inspected to deliver a flawless end product.

Logistics and transportation:

In the OEM foil balloon industry, timely delivery is critical as seasonal demands and promotions require quick turnaround. Efficient logistics planning, including inventory management and transportation coordination, is critical to meeting delivery deadlines. By partnering with a reliable logistics provider, manufacturers can ensure that products reach customers on time, every time.

After confirming the design of the OEM foil balloon, you need to arrange plate making and mold making to ensure that your desired design can be put into production as soon as possible.

Need custom foil balloons with personalized packaging? We offer OEM foil balloons that can be packaged with your paper card design, complete with straw and ribbon for a professional touch.

Instructions for inflating foil balloons

ABOUT INFLATING/DEFLATING/PASTING A BALLOON

(TIP: You need helium to lift the balloon)

Round mouth filling

1.Find the inflatable port in the middle of the transparent sheet

2.The pump is inserted into the inflation port

3.Slowly fill up the gas can be eight

4.Pinch down the pneumatic mouth of the adhesive will automatically seal

The flat inflatable

1.Find the inflatable port in the middle of the transparent sheet

2.The pump is inserted into the inflation port

3.Slowly fill up the gas can be eight

4.Pinch down the pneumatic mouth of the adhesive will automatically seal

Deflated method

1.Insert the suction pipe through the air hole until the air comes out

2.Press the OEM foil balloon gently with your hand until the gas glows

3.We're done.We can put it away

Paste method

1.Cut out a section of the scotch tape

2.The adhesive face is out wards so that the end of the cellophane is connected

3.Paste the scotch tape onto the balloon

4.Then stick the balloon on the wall

In summary, OEM foil balloon production is a complex process that requires careful planning and execution. From design conception to shipping, every step affects the final outcome of the product. By prioritizing efficient process and timeline planning, manufacturers can streamline production, maintain quality standards, and consistently meet customer expectations. In the highly competitive OEM foil balloon market, success lies in the ability to deliver innovative designs and high-quality products within the stipulated time.

Discover the power of custom OEM foil balloons for your brand. Elevate your next event with bespoke balloons. Contact us today!